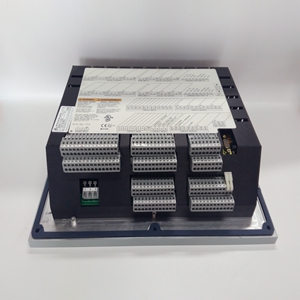

产品展示

联系我们

联系人:陈柳铭

手机:15579209656

电话:

Q Q:3136378118

邮箱:3136378118@qq.com

地址:江西省九江市瑞昌市东益路23号赛湖农商城401号

5461-774

是一个专用的燃气发动机控制单元,可执行多种典型的燃气

发动机控制功能,如:;空燃比控制、速度控制、负载控制和

失火检测。EGS-01支持爆震控制、数据和错误记录,

远程编程和监控以及CAN通信功能。这个

EGS-01与TecJet产品高度集成;这些产品组合为

旨在提供高度准确和灵活的燃油加注系统。

(产品规格36111)

燃气发动机输入/输出节点(GEION)与723 DCS结合可用于

在“闭环或开环”空燃比控制和

对于自然吸气或涡轮增压的化学计量气体发动机

范围为20至2000 kW。对于V型发动机,每个气缸组的空燃比控制为

可能使用两个燃气发动机输入/输出节点和一个723 DCS,每个气缸组一个。这个

燃气发动机输入/输出节点本身不适合进行空燃比控制。天然气

发动机输入/输出节点专门设计用于对渗碳器进行空燃比控制

涡轮增压或非涡轮增压燃气发动机。燃气发动机输入/输出节点接收

并通过网络将空燃比相关参数发送至723 DCS。

In-PulseTM系统已开发用于控制一系列Woodward

电动低压进气阀和电动液压高压轨

阀门。这些阀门提供了向发动机喷射燃油或其他液体的方法

在1至2100 rpm的速度范围内运行(范围取决于所使用的阀门

驱动)。板式电磁阀操作的进气阀(SOGAV)适用

仅用于歧管内喷射,而导轨阀提供缸内和歧管内型喷射装置的驱动。

(产品规范03543)

输入脉冲™ ll燃油喷射控制以电子方式管理和控制燃油

用于动力的喷射式(EFI)往复式发动机(燃气、柴油或双燃料)

发电、船舶推进、机车和工业发动机以及工艺

市场。In Pulse ll管理堆芯燃料系统和许多

电喷燃油系统,包括电子单体喷油器和泵(EUI/EUP),通用

索加夫铁路系统(C-R)™ 电磁阀操作的进气阀,微型先导

喷射系统和电子轨道阀(ERV)。

In Pulse ll可直接安装在发动机上,以承受高温

和振动环境。In Pulse ll也可以安装在附近的控制装置内

机柜(如需要)。

(产品规范03315)

萤火虫™ 控制检测汽油发动机爆震的发生,并调整

要补偿的点火正时。这样可以防止

敲击,从而提高效率。萤火虫使用放置在

发动机缸体。这些传感器拾取振动信号,萤火虫检测

与确定爆震条件相关的特定振动。萤火虫

确保只作用于爆震相关振动信号,忽略所有常见的

燃气发动机产生的振动信号。使用萤火虫,每个气缸可以

在各个循环期间单独分析。这样可以确保每个气缸都设置为

实现佳性能。可针对单个

气缸,从而改善排放和性能。(对于OEM应用

仅限)

is a dedicated gas engine control unit that performs multiple typical gas engine control functions such as; A/F ratio control, speed control, load control and misfire detection. The EGS-01 supports detonation control, data and error logging, remote programming and monitoring and features CAN communication. The EGS-01 is highly integrated with the TecJet product; these products combined are designed to provide a highly accurate and flexible fuel admission system. (product spec 36111) The Gas Engine I/O-Node (GEION) in combination with 723 DCS can be used for lean-burn gas engines running in both "closed or open loop" air fuel ratio control and for stoichiometric gas engines, naturally aspirated or turbocharged, in the power range of 20 to 2000 kW. In case of a V-engine, air fuel ratio control per bank is possible using two Gas Engine I/O-Nodes and a 723 DCS, one for each bank. The Gas Engine I/O-Node itself is not suitable to do the air fuel ratio control. The Gas Engine I/O-node is specially designed to do the air fuel ratio control on carbureted turbocharged or non-turbocharged gas engines. The Gas Engine I/O-Node receives and sends air fuel ratio related parameters to the 723 DCS via the network. The In-PulseTM system has been developed to control a range of Woodward electrical low pressure gas admission valves and electric-hydraulic high-pressure rail valves. These valves provide a means of injecting fuel or other fluids into engines operating within a speed range of 1 to 2100 rpm (range depends on the valve being driven). Plate type solenoid operated gas admission valves (SOGAVs) are suitable for in-manifold injection only, whereas the rail valve provides actuation of both incylinder and in-manifold type injection devices. (product spec 03543) The In-Pulse™ ll fuel injection control manages and controls electronically fuel injected (EFI) reciprocating engines (gas, diesel, or dual fuel) used in power generation, marine propulsion, locomotive and industrial engine, and process markets. The In-Pulse ll manages the core fuel system and injection events for many EFI fuel systems, including electronic unit injectors and pumps (EUI/EUP), common rail systems (C-R), SOGAV™ Solenoid Operated Gas Admission Valves, micro pilot injection systems, and electronic rail valves (ERV). The In-Pulse ll can mount directly on the engine, withstanding the high temperature and vibration environment. The In-Pulse ll can also be mounted inside nearby control cabinets if required. (product spec 03315) The FireFly™ control detects the occurrence of knock in gas engines and adjust the ignition timing to compensate. This provides protection from the harmful effects of knock and thereby increases efficiency. The FireFly uses knock sensors placed on the engine block. These sensors pick up vibration signals and the FireFly detects the specific vibrations associated with determining the knock condition. The FireFly ensures that only knock related vibration signals are acted upon, ignoring all usual vibration signals produced by a gas engine. Using the FireFly, each cylinder can be analyzed separately during individual cycles. This ensures that each cylinder is set to achieve optimum performance. Timing and/or load can be adjusted for individual cylinders, thus improving both emissions and performance. (For OEM applications only)

相关产品