产品展示

联系我们

联系人:陈柳铭

手机:15579209656

电话:

Q Q:3136378118

邮箱:3136378118@qq.com

地址:江西省九江市瑞昌市东益路23号赛湖农商城401号

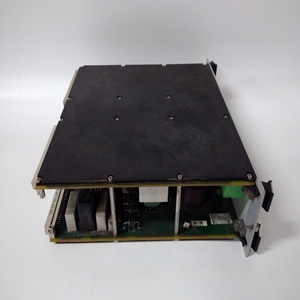

5461-656

设计用于电气

需要多机组负荷共享的发电机系统。2301A控制装置可能

用于柴油、燃气或汽油发动机,或蒸汽或燃气轮机。

控制装置可用于需要速降和/或同步速度的应用

控制在正向或反向作用模型中;对于单或串联致动器

安装;有加速或减速坡道;在多个速度范围内。

自动可调启动燃油限制可调节大燃油设定值,而

发动机正在起动。这有助于减少污染和发动机磨损。

每个2301A控制器都有一个独立的负载传感器。大多数型号提供0–200

mA输出信号;0–20 mA输出可用于特殊应用。输出

信号与达到所需速度/负载所需的燃油设定成比例。

不需要执行器的位置反馈。

(产品规格82390)

发电机采用2301D数字均载调速

需要负载共享的系统。可用于柴油或燃气发动机,

或蒸汽或燃气轮机。此控制采用基于数字的速度控制和

为PC通信提供单个串行端口。数字设计消除了

使用电位计进行调谐和负载控制。

(产品规范03204)

723 Plus数字控制可管理和控制往复式发动机(气体、,

柴油或双燃料)用于发电、船舶推进和燃气

压缩/分配。该控制装置也可用于热电联产、电力

输配电、过程管理、管道泵站、公用电力

发电、应急备用电源和远程控制站操作。723

Plus为新的和改装的情况提供先进的控制。

标准应用:(产品规范02759)

自定义应用:(产品规范02876)

723压缩机性能控制,基于Woodward强大的

723PLUS/828数字控制平台,控制速度、空燃比和点火

变速/负载应用中往复式发动机的正时。控件

包括两个速度传感器(MPU或接近型)的输入,带有触发扭转滤波器,

用于监测发动机和涡轮增压器转速(或冗余发动机转速

传感),用于衰减挠性耦合扭转影响的陷波滤波器,远程

速度设置输入,以及空气歧管压力、燃气集管压力、,

以及具有3D曲线的空气歧管温度,用于映射空燃比和

点火正时设置。提供离散上升/下降输入以调整空气歧管

压力和发动机转速设置。

(产品规范03214)

733数字控制管理和控制往复式发动机(燃气、柴油或

双燃料)用于发电、船舶推进、机车和工业

发动机和工艺市场。733经过专门设计,使其能够

直接安装在发动机上,可承受高温和振动

环境如果需要,733也可以安装在控制柜内。

733是一个独立的速度控制装置,具有功能和配置

与其他伍德沃德数字控制类似,如723(包括即插即用

伍德沃德项目的网络连接™ 数字执行器系列,用于可安装在发动机上的等位电子控制解决方案),并可作为

发动机管理系统中的主控制单元。该控件设计用于

与其他伍德沃德或客户选择的设备(如I/O)的网络连接

模块(远程或集成在733组件内)、执行器、点火控制、,

空气/排气和燃油流量控制阀、电源管理控制和EFI

电磁阀驱动器。可对其进行编程以执行所有发动机功能,如

速度、空气和燃油控制、监控、报警、发动机保护和排序。

are designed for use in electric generator systems where multi-unit load sharing is desired. 2301A controls may be used with diesel, gas or gasoline engines, or steam or gas turbines. Controls are available for applications requiring droop and/or isochronous speed control; in forward- or reverse-acting models; for single or tandem actuator installations; with accelerating or decelerating ramps; and in several speed ranges. Automatic, adjustable start fuel limiting regulates the maximum fuel setting while the engine is starting. This helps decrease pollution and engine wear. Each 2301A control has a self-contained load sensor. Most models provide a 0–200 mA output signal; 0–20 mA output is available for special applications. The output signal is proportional to the fuel setting needed to attain the desired speed/load. Position feedback from the actuator is not required. (product spec 82390) The 2301D Digital Load Sharing and Speed Control is used in electric generator systems for which load sharing is desired. It can be used with diesel or gas engines, or steam or gas turbines. This control utilizes a digital based speed control and provides a single serial port for PC communications. The digital design eliminates the use of potentiometers for tuning and load control. (product spec 03204) The 723 Plus Digital Control manages and controls reciprocating engines (gas, diesel, or dual fuel) used in power generation, marine propulsion, and gas compression/distribution. The control may also be used in cogeneration, power transmission/distribution, process management, pipeline pump stations, utility power generation, emergency standby power, and remote control station operation. The 723 Plus provides state-of-the-art control for new and retrofit situations. Standard Applications: (product spec 02759) Custom Applications: (product spec 02876) The 723 Compressor Performance Control, based on Woodward’s powerful 723PLUS/828 digital control platform, controls the speed, air/fuel ratio, and ignition timing of reciprocating engines in variable speed/load applications. The control includes inputs for two speed sensors (MPU or proximity) with firing torsional filters, for monitoring engine and turbocharger speed (or for redundant engine speed sensing), a notch filter to attenuate the effect of flexible coupling torsionals, a remote speed setting input, and inputs for air manifold pressure, fuel gas header pressure, and air manifold temperature with 3D curves for precisely mapping air/fuel ratio and ignition timing settings. Discrete raise/lower inputs are provided to adjust air manifold pressure and engine speed settings. (product spec 03214) The 733 Digital Control manages and controls reciprocating engines (gas, diesel, or dual fuel) used in power generation, marine propulsion, locomotive and industrial engine, and process markets. The 733 has been specifically designed to enable it to be mounted directly on the engine, withstanding the high temperature and vibration environment. The 733 can also be mounted inside control cabinets if required. The 733 is available as a standalone speed control with functions and configuration similar to other Woodward digital controls such as 723 (including plug-and-play network connectivity to the Woodward ProAct™ Digital Actuator family for an allelectric governing solution that can be engine mounted), and it is available as the main control unit within an engine management system. The control is designed for network connectivity to other Woodward or customer-selected devices, such as I/O modules (remote or integrated within the 733 package), actuators, ignition controls, air/exhaust and fuel flow control valves, power management controls, and EFI solenoid drivers. It may be programmed to perform all engine functions such as speed, air and fuel control, monitoring, alarms, engine protection and sequencing.

相关产品